Scaling often occurs during the operation of heat exchange equipment,

which causes significant thermal resistance, reducing the heat transfer

performance of the equipment, shortens its service life, and increasing

the cost of use and maintenance. Ultrasonic descaling heat exchangers

can effectively avoid the generation of scale and improve the efficiency

of equipment utilization.

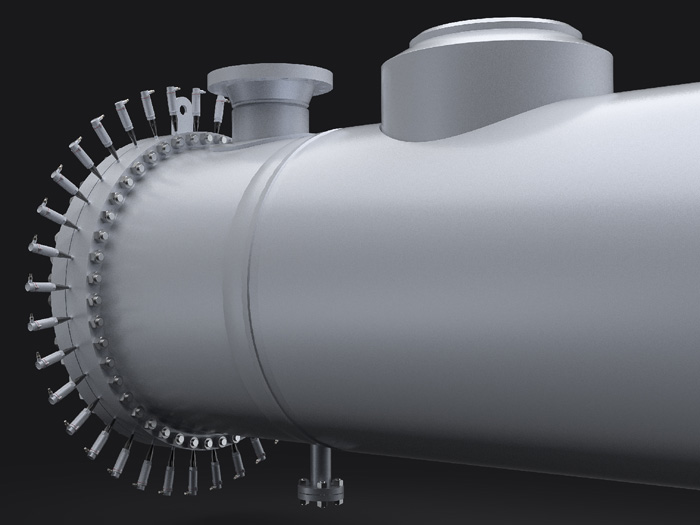

The ultrasonic descaling heat exchanger

consists of a regular heat exchanger and an ultrasonic descaling

device. The device uses a strong ultrasonic field to treat the fluid,

causing a series of changes in the physical form and chemical properties

of the scaling substances in the fluid under the action of the

ultrasonic field, making them dispersed, crushed, loose, and not easily

attached to the pipe wall to form scale.

Ultrasonic descaling heat

exchangers are particularly suitable for single tube and two-tube shell

and tube exchangers. The use effect of fixed tube sheet heat exchangers

with exposed tube sheets is better.

The descaling device used in

the ultrasonic descaling heat exchanger consists of an ultrasonic power

supply and an ultrasonic transducer, and one power supply can support

one or more transducers.

1 . Advantages of ultrasonic descaling heat exchanger:

1).

Online scale prevention (removal) does not require production shutdown,

with prevention as the main focus, and basically achieves scale free

operation.

2). Physically prevent (remove) scale without adding any chemicals, environmentally friendly.

3). The descaling device is installed on the outer wall of the tube

plate to prevent the formation of scale bodies inside the tube bundle.

4). Can simultaneously remove dirt on the outer wall of the tube bundle that cannot be cleaned by personnel.

5). A regular heat exchanger can be installed with a descaling device

in operation, which is convenient to install, has a short construction

cycle, occupies small space, and does not affect production.

6). The product is energy-saving and has low operating power, maintenance free, and low operating costs.

2. The anti-scaling mechanism of ultrasonic descaling heat exchanger is mainly manifested in:

1). The "cavitation" effect. 2). The 'shear' effect. 3). Activation effect. 4). The "inhibitory" effect.

3. Safety and reliability of ultrasonic descaling heat exchanger

1).

Electromagnetic compatibility: During the development process of the

ultrasonic descaling device, consideration was given to preventing the

impact of other electrical equipment

and the influence of other

electrical equipment on the ultrasonic pulse descaling device itself,

making it compatible with the power grid and other electrical equipment.

2). The protection level of ultrasonic descaling devices is divided

into IP32, IP55, IP56, etc. according to different usage locations, and

the products comply with general electrical,

explosion-proof electrical, marine electrical and other standards.

3). The maximum amplitude of the ultrasonic descaling device is 10 μ

m. The amplitude of metal fatigue is 40 μ m. Therefore, it will not

cause damage to the components.

|